The original 700 Series of extra-heavy trucks was introduced to the local market in 2004 and underwent an upgrade and equipment enhancement in 2019. Now, the 2023 model takes big steps forward in terms of its technology, with huge benefits regarding active and passive safety systems as well as improved fuel economy, all of which contribute to a lower total cost of ownership.

“Our current ranges of 200 and 300 Series medium trucks are proving very popular as is our 500 series in the heavy truck segment and now we will also have a strong competitor in the high volume, extra-heavy category,” explained Anton Falck, the recently appointed Vice President of Hino South Africa. “Minimising downtime for our customers was a prime aim with the redesign of this important model.”

The latest 700-Series is a major step up from its predecessors in terms of the extensive safety technologies that are offered as standard features. It also constitutes a completely redesigned cab which ensures greater comfort for the driver, while weight reduction improves the 700 Series’ operating efficiency. There is also more convenient access to the engine for service and maintenance activities.

The exterior of the Hino 700 Series has undergone its first major design change in 14 years, with aerodynamic and safety benefits. From the bold grille, which has a three-dimension appearance, to the sharply styled headlamps, this range-topping truck has a new frontal appearance, while the restyling of the cab has made it more spacious for the driver. The interior has been completely redone too, with major focus on improving comfort and ergonomics to cut driver fatigue. It is also easier to get in and out of the new cab.

There is a compact range of four basic models, being a tipper, a freight carrier, and two truck-tractors, all 6×4 configurations. The new range is powered by derivatives of the proven and reliable 13-litre Hino E13C six-cylinder turbocharged and intercooled diesel engine. The 2841 models are fitted with one version of this engine, developing 302 kW (410 hp) between 1 500 and 1 800 r/min, together with a peak torque of 1 961 N.m between 1 400 and 1 800 r/min. The high-powered 2845 truck tractor utilizes an engine model that produces 331 kW (450 hp) between 1 500 and 1 800 r/min, with a peak torque of 2 157 N.m between 1 050 and 1 400 r/min.

There are several fuel-saving changes including the switch from a variable nozzle type turbocharger to a conventional type that facilitates a weight reduction of 13 kg. Significant fuel saving is possible when the standard Eco Mode system is used.

Both engines are mated to a ZF 16-speed Traxon automated manual transmission, offering fully automatic shifting with optional manual override. This makes it not only easier on the driver but also saves fuel with optimised gear selection. Protection against abuse in both modes is always active.

A major change has been made in the redesign of the rear suspension resulting in a 20% weight reduction while performance is retained. Front and rear suspension is by leaf springs, while the power-assisted, variable ratio rack and pinion steering now has a variable hydraulic pump as a contributor to saving fuel.

However, the big news is the important enhancement of the safety aspects of the 700 Series.

Koyo, Goto the Chief engineer for the 700 Series, had this to say “We, at Hino Motors in Japan, have aimed to enhance safety through the adoption of active driver support systems and preventive safety systems, as well as improving driver comfort with a much quieter cab, and improved ride comfort. The new, high-functionality seats can accommodate a wider range of driver body heights in comfort which will reduce fatigue and improve driving efficiency. I am confident that we have succeeded in developing a truck that provides a safe and comfortable working environment.”

There are several safety systems in the new Hino 700 Series that work individually or collectively to prevent a collision or to lessen the damage.

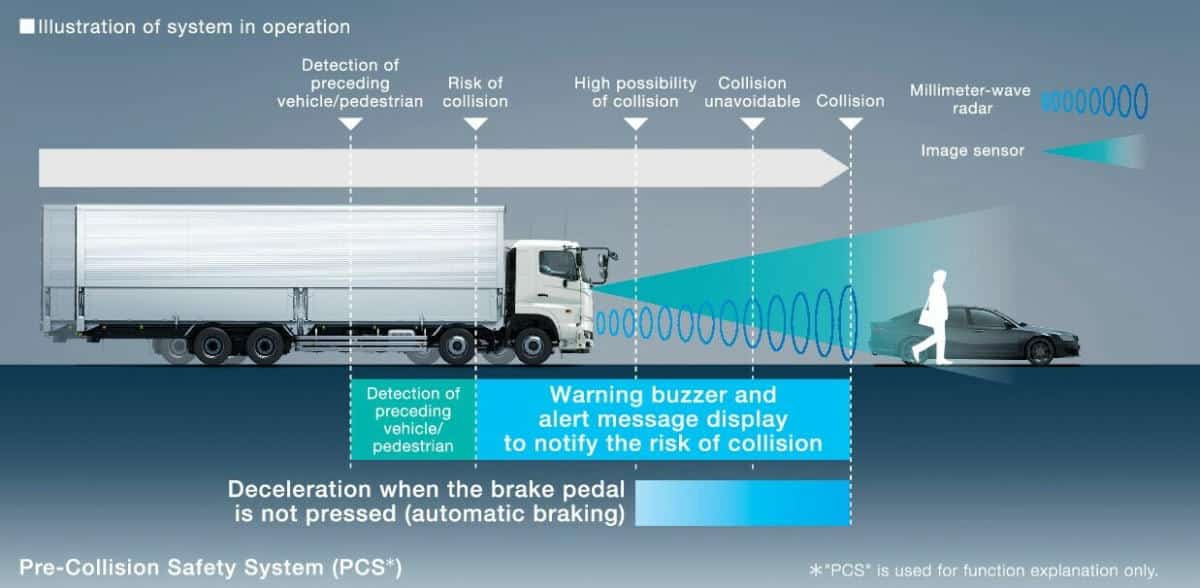

Firstly, there is the Pre-Collision System (PCS) which uses a millimetre wave radar and an image-based sensor to predict a vehicle or pedestrian on the road ahead. If the system judges that there is a highly probable risk of a collision, it uses audible and visual warnings to inform the driver as well as using brake control support to avoid a collision or to reduce collision damage. The system will assist the driver’s force on the brake pedal, while the truck will decelerate even if the driver fails to push the brake pedal.

Secondly, there is a Lane Departure Warning System (LDWS) which uses an image-based sensor installed on the front windshield of the vehicle to detect the lane markings ahead. A warning buzzer and dashboard display alerts the driver if the truck deviates from the lane in which it is driving.

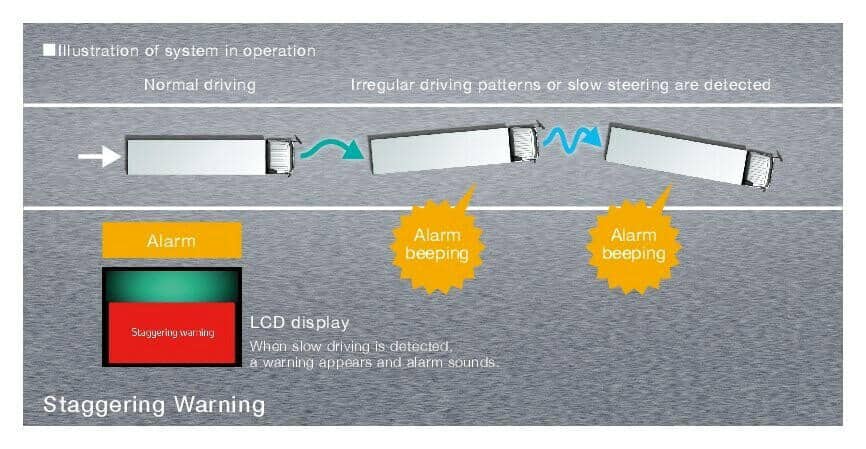

Thirdly, the Staggering Warning (SW) which alerts the driver if the truck starts weaving over the road. If the staggering continues without being addressed by the driver, then the PCS prepares to activate quickly.

A further safety feature is the Driver Monitor Camera (DMC) which constantly checks the driver’s posture, face direction, and the state of the eyelids – open or closed. If the system detects insufficient driver focus on the road in front of the truck, then the driver is alerted with a buzzer and a warning message on the dashboard to help prevent a collision. The rear-view mirrors have been revised and much improved to assist driver vision of conditions around the truck.

Another standard feature of the latest Hino 700 Series is Adaptive Cruise Control (ACC) which uses a millimetre wave radar to detect preceding vehicles. It then automatically maintains an appropriate vehicle-to-vehicle distance. This reduces the need for accelerating and brake operation by the driver, contributing to reducing fatigue.

The vehicle-to-vehicle distance control operates between speeds of approximately 35 km/h and 90 km/h. The system gives a warning if the distance between the vehicles suddenly becomes too short and there is a possibility of a collision and automatically activates the PCS.

All models have engine retarders as standard, while the Freight Carrier and TT models have ZF intarders for additional brake assistance fitted as standard. This, together with a safety airbag for the driver, anti-lock brakes, seat-mounted seat belts and side impact beams in the doors complete a comprehensive vehicle and driver safety package.

The complete redesign of the cab includes a much easier to read speedometer and tachometer while the size of the multi-information display between them is doubled. The selected gear and range (Hi/Lo) are prominently displayed, together with Eco Mode, time, water temperature, fuel level, total distance meter, and tripmeter.

The new 700 Series is the first Hino in South Africa to feature multi-functional controls on the steering wheel. These operate the multi-information display and cruise control without the need for the driver to take his or her hands off the steering wheel. There are also controls for the Bluetooth audio and hands-free operation of the telephone. Air conditioning, an AM/FM audio system with CD player, USB, AUX and Bluetooth, electric windows, central locking, and a transponder immobiliser key are all standard.

Night-time driving is also much improved with halogen type lights for the low beam.

The new Hino 700 Series truck range is covered by one of the most comprehensive warranties for extra-heavy trucks in South Africa. The vehicle, powertrain and chassis frame warranties on the tipper are for 24 months, irrespective of distance covered, while the other models have 36-month warranties. There is a 48 month/unlimited distance warranty on cab corrosion.

A range of Hino-Care service and maintenance plans can be tailored by the dealer to meet a customer’s requirements.

Service intervals are every 15 000 km / 250 hours for the tipper and every 30 000 km for the other models, although these may change depending on operating conditions.

HINO-CONNECT, a full fleet management system, is installed as a standard fitment on the new 700 Series. This is a joint venture with Cartrack, an international mobility solutions provider.

“This comprehensive telematics solution includes a three-year subscription from date of fitment and will be an important, additional tool to ensure we continue to provide the highest levels of customer satisfaction,” explained Anton Falck.

“Hino’s Total Support strategy, which builds strong relationships and trust with all stakeholders, and has been the backbone of our success here in South Africa for many years, will benefit hugely from the data this system will now be able to provide to our customers, Hino South Africa and Hino Japan.”

HINO-CONNECT provides three sets of data:

- Positional data for tracking and recovery as well as distances travelled.

- Vehicle performance data including fuel consumption, oil and water temperatures and speed.

- Diagnostic Trouble Code (DTC) fault reporting direct to Hino SA and the dealer concerned, who will know what is wrong before getting to the vehicle, thereby enabling quicker reaction time to get the vehicle back on the road.

All data is stored for five years, with the last six months’ data available immediately.

New Hino 700 series range:

| Model | Type | Power | Torque | Tare | GVM |

| 2841 | 6×4 Tipper | 302 kW (410 hp) | 1 961 N.m | 8 640 kg | 28 300 kg |

| 2841 | 6×4 F/C | 302 kW (410 hp) | 1 961 N.m | 9 030 kg | 28 300 kg |

| 2841 | 6×4 TT | 302 kW (410 hp) | 1 961 N.m | 9 605 kg | 28 300 kg |

| 2845 | 6×4 TT | 331 kW (450 hp) | 2 157 N.m | 9 605 kg | 28 300 kg |

Content and images supplied via MotorPress