- With five years of research and design and a budget of around one trillion Lire, it was the most significant investment Fiat had made up until then in a vehicle.

- Robogate, a sophisticated production system for the assembly of car bodies, entered the factory to provide precision and absolute flexibility.

- In 1985 this “dance” of the robots also took place in the Termoli factory, where the new FIRE engine was created. The Uno was the first Fiat vehicle to use it.

- With the Fiat Uno, a new and fruitful relationship was established between the Centro Stile and Engineering, which became more united thanks to the new CAD stations and the emerging concept of Functional Design.

- Heritage Stellantis’ team (Alfa Romeo, Fiat, Lancia, Abarth) has made an evocative video in which Roberto Giolito, Head of Stellantis Heritage speaks about this gamechanger.

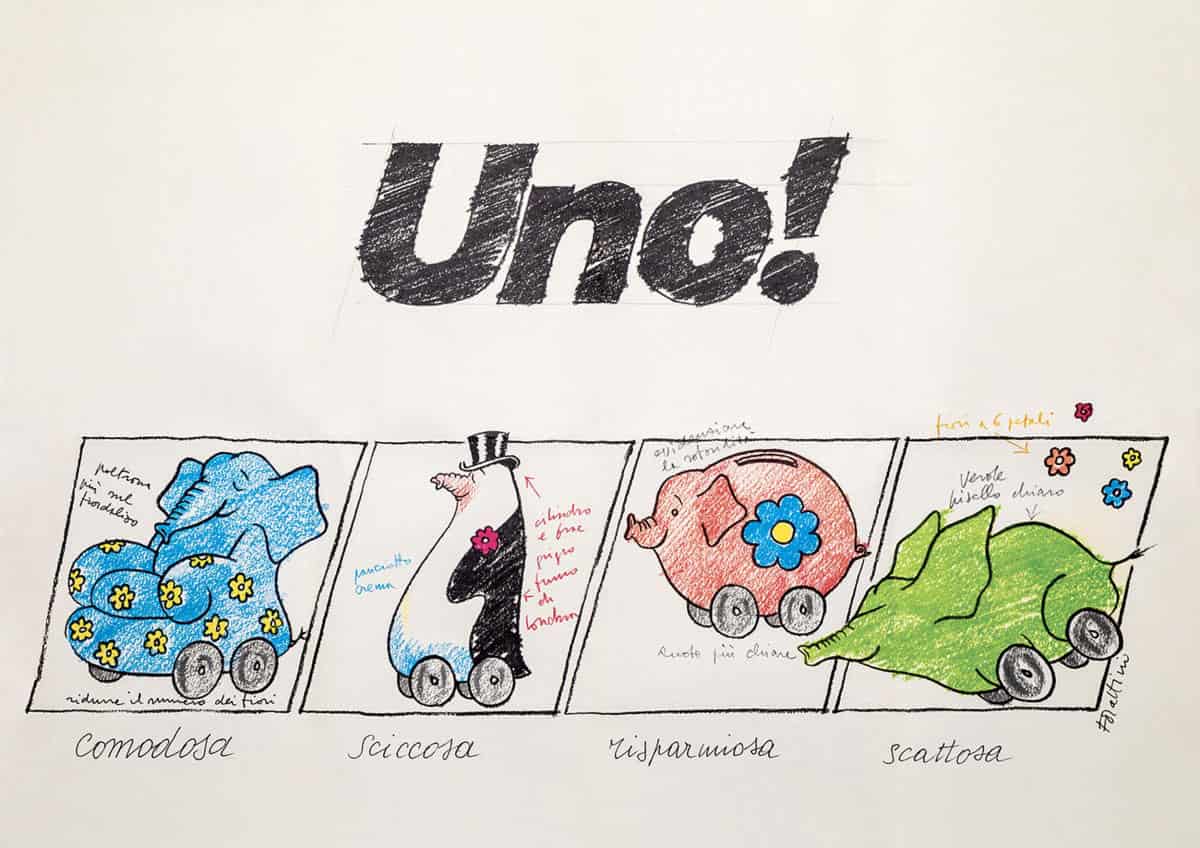

After having recounted the story of the Fiat Uno’s “rivoluzionosa” ad campaign, Heritage Stellantis’ team now presents a second video which reveals how special this Fiat icon created 40 years ago is in terms of technological innovation applied to design and production. Roberto Giolito, Head of Stellantis Heritage (Alfa Romeo, Fiat, Lancia, Abarth), takes viewers on this journey with images from the Centro Storico Fiat and memorabilia conserved at the Heritage Hub, which can be visited by booking a guided tour at the following link.

Technological innovation is the common thread which runs through the Fiat Uno’s 40 years of history, as demonstrated by its spectacular debut in front of the international press on January 19, 1983, at Cape Canaveral (USA), a city representing the conquest of outer space. It was the perfect setting for a model destined to redefine the paradigm of city cars and change the history of the Italian brand.

The Fiat Uno represents a sea change in the automotive sector thanks to the achievement of various firsts: the extensive use of robots in the production process, a new and fruitful relationship between the Centro Stile and Engineering, and the establishment of what today we call Functional Design. Everything was designed to obtain the highest level of quality, which is exactly what one would expect from the most innovative model in the segment. A notable leap in quality was made thanks in part to considerable financial investment made. In fact, with five years of research and design and a budget of about one trillion Lire, it was the most significant investment Fiat had made in a vehicle up until then.

Roberto Giolito, Head of Stellantis Heritage (Alfa Romeo, Fiat, Lancia, Abarth) stated that “the Uno was a completely innovative project, starting with its body which, unlike its 127 predecessors, was designed to be made with robotic welding. The same doors were assembled with fewer components and the new tailgate also removed the weld line which previously had been perceived as a flaw and now had become a distinctive design for the side.”

The Robogate, spearheading factory automation

With the Fiat Uno a new conception of production took shape which would lead to an Integrated Factory geared to greater flexibility. The cornerstone of this industrial philosophy was the Robogate, a sophisticated production system designed by Comau, a leading company in automation of the Gruppo Fiat, for the assembly of car bodies which was mainly based on a precise spot-welding system for each single piece of the vehicle. Its debut took place in 1978 at the Rivalta factory with the production of the Ritmo but was soon used at the Mirafiori and Cassino plants. The Fiat Uno would make use of this system and take advantage of dozens of robots for the assembly, welding and coating phases, significantly improving the uniformity and quality of the production. A majority of the overall investment in the “Uno” project went into factory automation. Each day a spectacular “dance” took place with mechanical arms, lifts and gates, whose timing and processes were managed by a computer.

“The Fiat Uno was not only part of a manufacturing revolution, it changed the entire way of conceiving, developing, and producing a car. From the CAD design desks to the factory, everything became part of a continuum and managed by a single system,” stated Giolito. “If today dedicated networks and hardware connections link various areas of the plant, tomorrow it will be the concept of the “Internet of Things” which will rule and create a dialogue between these machines to reach the greatest flexibility possible. This will allow for the construction of cars for every continent and culture in the most efficient and sustainable way possible.”

The FIRE engine, the Gruppo Fiat’s technological gem

Robots also entered into the futuristic factory of Termoli 3, specifically created in 1985 for the construction of the new FIRE motor, whose history is closely connected to the Uno’s. It was the first vehicle to be equipped with this gem of Italian engineering which was produced for 35 years and in over 23 million units. Its name is an acronym for Fully Integrated Robotized Engine and refers to the innovative method with which it was created, i.e., the Robogate system. Compared to the previous engine used on all Fiat vehicles, the new FIRE was more compact and lighter (just 69 kg), simpler in its design philosophy (with 95 components less), more modern (going from a rods and rockers system to one with an overhead camshaft), more reliable, and easier to assemble. In short, it was a long-lasting project and featured engine engineering which would become part of the collective imagination and synonymous with reliability and quality.

Engineering and the Centro Stile, more closely linked by instruments and objectives

With the Fiat Uno, even the way vehicles were designed was revolutionized, and drafting tables were replaced by CAD stations. Computer-assisted design allowed for precision and reduced tolerances to zero, a part of manual design which was always subject to some human error. The relationship between the Centro Stile and Engineering also changed; they began to collaborate more closely and looked for solutions capable of combining design with function and aesthetic beauty with rationality.

These were the years in which, even at the level of the automotive group, the company was proud to show off common components or modular parts which were used to make vehicles for other brands as well. Moreover, at the beginning of the Eighties, Fiat’s Centro Stile became a multi-brand design studio thanks to the style coordination of the Group’s brands and played a greater role in the greater technical management (what today we call Engineering Management). In this genuine hotbed of innovative ideas, non-stop dialogue was also developed with the body shops of the time, including the newly formed Italdesign of Giorgetto Giugiaro (which would design the Fiat Uno) and the Bertone, Pininfarina, and the soon-to-be-founded, Idea Institute studios.

The birth of the concept of Functional Design

The Fiat Uno was ahead of the European tendency in this segment to offer a body with a windshield which leaned more towards the front, as if it had a “single volume” form. Additionally, the increased slope of the hood united the front window and the hood itself. The rear window was totally flush while, for the first time, the rain gutter above the door was eliminated. Thanks to factory robots, the roof welding with the side took place via famous “suspenders”. This all allowed for greater accessibility and ease in entering and exiting the vehicle. Additionally, all it took were a few centimeters to raise the driver seat, allowing for unmatched road control and maneuverability.

The Fiat Uno was almost an immediate success. It was loved by the market and by sector professionals who voted it as the Car of the Year in 1984. Its main strengths were its large cabin, which hosted up to five people, and spacious trunk, which was easily accessible from the tailgate. It was also appreciated for its innovative dashboard with two knobs on the sides of the instrument panel from which almost everything could be controlled. Only the turn signal used the conventional switch behind the steering wheel while the climate controls were centered, lower, and under the air vents. It also included an effective single central windshield wiper which was equipped with intermittence and various speeds.

Roberto Giolito concluded by stating that “The Fiat Uno is an archetype which was copied by many competitors and paved the way for them to introduce their products. However, Fiat would continue to be the clear leader in this segment, so much so that an electronic-injection turbo version would break ground for compact yet sporty hatchbacks.

Content and images supplied via QuickPic